- Industries

- Resources

Resources

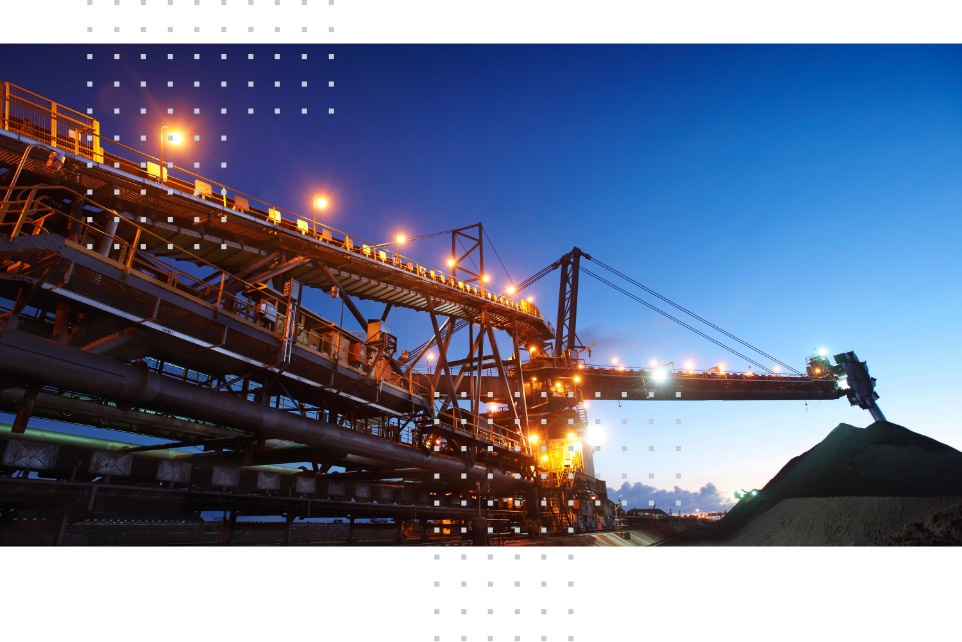

Delivering safe and reliable automation solutions in tough environments

Smart, secure automated control solutions for the resources industry. Enquire now

Why you need the best automation solutions

Resource sites are tough environments – they are high pressure, isolated, potentially dangerous and they often operate around the clock. In these sorts of environments, there is an extremely low tolerance for things going wrong. That is why you need smart, secure automated control and safety solutions that promise certainty.

With extensive experience in the resources sector, in mining, minerals, oil and gas, SAGE delivers exactly what you need, precisely when you need it.

What we can do for you

SAGE has a proven track record in automated solutions that help to improve efficiency, quality and safety.

From exploration, extraction, processing and refining through to the end use and transfer to market, we offer expertise at every step of the production process.

SAGE provides PLC, SCADA/HMI, DCS and RTU solutions for all sectors, together with sophisticated wired and wireless communications systems. We also have extensive experience with manufacturing execution systems (MES) and manufacturing intelligence (MI), and can provide remote mine camp utility solutions.

We are proud to count some of the biggest names in resources among our customers, including BHP, Santos and Boart Longyear.

No matter what challenges your business is facing, SAGE Automation can help.

Mining

SAGE understands that success in the mining industry depends on reducing the ongoing cost of exploration and the delivery of a high-quality product. SAGE provides integrated automation and process controls to form customised solutions for complex mining challenges.

Minerals

SAGE works closely with our customers to develop innovative solutions as projects mature and develop. This flexible approach delivers exceptional value and outcomes to customers and reduces project risk.

Oil and gas

SAGE supports the country’s largest oil and gas projects, developing custom solutions for oil and gas applications. SAGE understands the importance of up-front design and document sign-off to ensure projects are completed safely.

SAGE can also deliver security and safety in the distribution of oil and gas around Australia. More than just moving product from A to B, SAGE provides turnkey solutions that ensure complete security and control, with real-time data to ensure quotas and demands are met.

Why SAGE is the best choice for your resourcing needs

We deliver certainty

In tough, isolated environments, you can’t afford to be second-guessing your automated control and safety systems. We always deliver what we say we will – and no challenge has had us stumped yet.

Why SAGE is the best choice for your resourcing needs

We deliver the best thinking

SAGE boasts a large, mobile and scalable resource pool to support your remote operation with quality engineering. Our very broad skillset means we can draw expertise and innovation from other industries, including infrastructure and manufacturing, so you get the best possible solution.

Why SAGE is the best choice for your resourcing needs

We are serious about safety

We know that on isolated sites, safety is of paramount importance. That is why we take safety very seriously, and consider it in the context of everything we do.

SAGE is tri-certified with international certifying body DQS for Quality, OH&S and Environmental Management Systems, complying with; ISO 9001, AS 3000 (Electrical), ISO 14001 (Environmental) and ISO 45001 (OH&S).

Why SAGE is the best choice for your resourcing needs

We are independent

At SAGE, we are not tied to any one supplier. Our goal is always to provide the very best solution for the issue at hand, no matter what products you’re using.

Buyers across the resources industry are invited to view our pre-qualification certification with leading supplier management organisations Achilles, ISNetworld and CM3.

Why SAGE is the best choice for your resourcing needs

We value our relationships with our customers

We will collaborate with you closely throughout the project to ensure we deliver the outcome you want. Cultivating strong relationships with our customers is important to us – that is one reason why SAGE has been operating offices in Whyalla and Olympic Dam for more than 5 years, allowing us to be fully responsive to the needs of Arrium and BHP Billiton respectively.

Why SAGE is the best choice for your resourcing needs

We understand the resources sector

We have an intricate working knowledge of the legal and environmental regulations of the sector, and a deep understanding of the demands of remote sites. We also have resource management strategies in place to ensure optimal project outcomes in remote areas.

Resources capabilities

Oil and Gas Distribution

- Turnkey industrial automation projects

- Turnkey automation and control systems to enhance the safety, efficiency and quality of mining operations

- Design, manufacturing and installation of PLC, HMI/ SCADA, DCS and RTU solutions

- Wide area telemetry and networking

- Upgrading and replacing aging systems

- Conveyor systems

- Mine water management

- Underground equipment monitoring

- Mobile control rooms

- Ship loading systems

- Pipeline control systems

- Bore management and water processing

- Crushing and thickening control solutions

- Materials handling control

- Storage facility control systems

- Quality tracking systems

- Relocatable switch rooms

- Distributed Control Systems (DCS) to plant integration

- Safety management

- Safety audits and compliance recommendations

- Meeting government regulations and Australian Standards

- Machine safety control system design, build and installation

- Hazardous area design

- Leak detection

- Cost/margin management

- Waste reduction

- Process improvemnt

- Energy usage monitoring

- Information gathering and implementation of Manufacturing Execution Systems (MES) and Manufacturing Intelligence (MI)

- Uptime maximisation

- Quality management

- Yield maximisation

- Product traceability/quality tracking systems

- End-to-end support

- Service and support of mining automation and control systems

- Advanced technology training

- Workforce mobility

- Camp utilities infrastructure

Oil and gas extraction

- Turnkey industrial automation projects

- Turnkey automation and control systems to enhance the safety, efficiency and quality of mining operations

- Design, manufacturing and installation of PLC, HMI/ SCADA, DCS and RTU solutions

- Wide area telemetry and networking

- Upgrading and replacing aging systems

- Conveyor systems

- Mine water management

- Underground equipment monitoring

- Mobile control rooms

- Ship loading systems

- Pipeline control systems

- Bore management and water processing

- Crushing and thickening control solutions

- Materials handling control

- Storage facility control systems

- Quality tracking systems

- Relocatable switch rooms

- Distributed Control Systems (DCS) to plant integration

- Safety management

- Safety audits and compliance recommendations

- Meeting government regulations and Australian Standards

- Machine safety control system design, build and installation

- Hazardous area design

- Leak detection

- Cost/margin management

- Waste reduction

- Process improvemnt

- Energy usage monitoring

- Information gathering and implementation of Manufacturing Execution Systems (MES) and Manufacturing Intelligence (MI)

- Uptime maximisation

- Quality management

- Yield maximisation

- Product traceability/quality tracking systems

- End-to-end support

- Service and support of mining automation and control systems

- Advanced technology training

- Workforce mobility

- Camp utilities infrastructure

Minerals

- Turnkey industrial automation projects

- Turnkey automation and control systems to enhance the safety, efficiency and quality of mining operations

- Design, manufacturing and installation of PLC, HMI/ SCADA, DCS and RTU solutions

- Wide area telemetry and networking

- Upgrading and replacing aging systems

- Conveyor systems

- Mine water management

- Underground equipment monitoring

- Mobile control rooms

- Ship loading systems

- Pipeline control systems

- Bore management and water processing

- Crushing and thickening control solutions

- Materials handling control

- Storage facility control systems

- Quality tracking systems

- Relocatable switch rooms

- Distributed Control Systems (DCS) to plant integration

- Safety management

- Safety audits and compliance recommendations

- Meeting government regulations and Australian Standards

- Machine safety control system design, build and installation

- Hazardous area design

- Leak detection

- Cost/margin management

- Waste reduction

- Process improvemnt

- Energy usage monitoring

- Information gathering and implementation of Manufacturing Execution Systems (MES) and Manufacturing Intelligence (MI)

- Uptime maximisation

- Quality management

- Yield maximisation

- Product traceability/quality tracking systems

- End-to-end support

- Service and support of mining automation and control systems

- Advanced technology training

- Workforce mobility

- Camp utilities infrastructure

Mining

- Turnkey industrial automation projects

- Turnkey automation and control systems to enhance the safety, efficiency and quality of mining operations

- Design, manufacturing and installation of PLC, HMI/ SCADA, DCS and RTU solutions

- Wide area telemetry and networking

- Upgrading and replacing aging systems

- Conveyor systems

- Mine water management

- Underground equipment monitoring

- Mobile control rooms

- Ship loading systems

- Pipeline control systems

- Bore management and water processing

- Crushing and thickening control solutions

- Materials handling control

- Storage facility control systems

- Quality tracking systems

- Relocatable switch rooms

- Distributed Control Systems (DCS) to plant integration

- Safety management

- Safety audits and compliance recommendations

- Meeting government regulations and Australian Standards

- Machine safety control system design, build and installation

- Hazardous area design

- Leak detection

- Cost/margin management

- Waste reduction

- Process improvemnt

- Energy usage monitoring

- Information gathering and implementation of Manufacturing Execution Systems (MES) and Manufacturing Intelligence (MI)

- Uptime maximisation

- Quality management

- Yield maximisation

- Product traceability/quality tracking systems

- End-to-end support

- Service and support of mining automation and control systems

- Advanced technology training

- Workforce mobility

- Camp utilities infrastructure

Jonathan Deluao, Principal Control Systems/Maintenance Engineer, Arrium Mining

“The new crushing and screening plant has had a number of design revisions, but as it is modular and mobile, it has been easy to adapt to changes,”More to explore

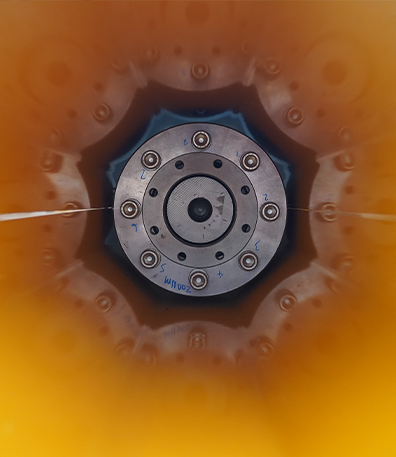

SAGE provides OEM support for world-first drill rig

A mining client engaged SAGE for OEM support for a solution to measure the torque, power, current, and engine speed of its world-first drill rigs.

Automating the driverless railcars vital to mining sector

SAGE supported Metso’s railcar dumper system with tailored PLC and SCADA packages and ongoing service…

Underground explosives ignited via custom control system

SAGE engineering ensures an underground mining explosives system is flexible, rugged and safe.

Industry Engagement

SAGE is a member of the Mining Industry Skills Council.

Talk to us about...

Recent posts

Let's work together and start saving you both time and money.

Emergency breakdown support 24/7:

Ph: 1800 724 373

For other enquiries:

Ph: 1300 00 SAGE (1300 00 7243)

info@SAGEAutomation.com