At the end of last year, The Australian Industry Group (The Ai Group), released their annual business strategy report.

The report analyses the key business priorities across a range of industries such as construction, ICT, manufacturing and mining, and evaluates whether those priorities are paying dividends.

The report unearthed some interesting findings, not just about the state of play of Australian business as a whole, but particularly for manufacturers. So what were the key outcomes and what can manufacturers take away from the report?

Key priorities for Australian manufacturing businesses.

The report found that implementing a growth strategy was a key priority for manufacturing companies. 91% of manufacturers implemented a growth strategy in 2016.

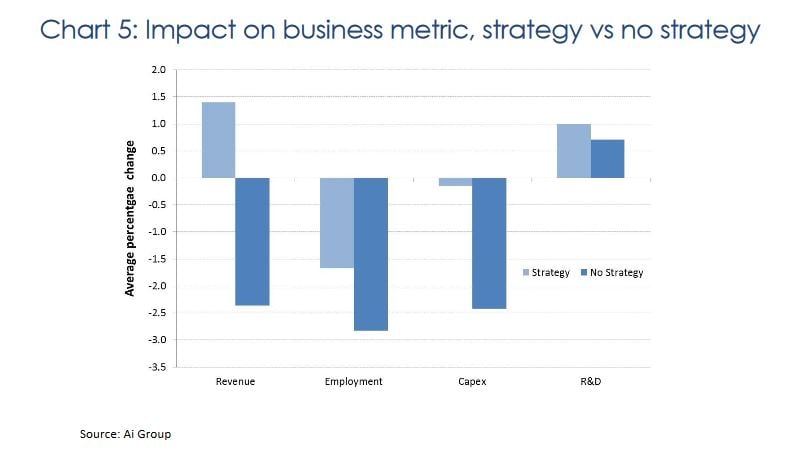

After reviewing results from 2014 to 2016, the Ai Group found businesses with a growth strategy saw lower levels of layoffs, less reduction in capital expenditure and undertook higher levels of research and development.

For manufacturers, there are two core components that inform their growth strategy:

- The introduction of new products and services

- Improving on existing products and services

Investment is a key priority

Given that manufacturing’s mantra is to do more with less, one could assume that there would be a focus on reducing operational costs.

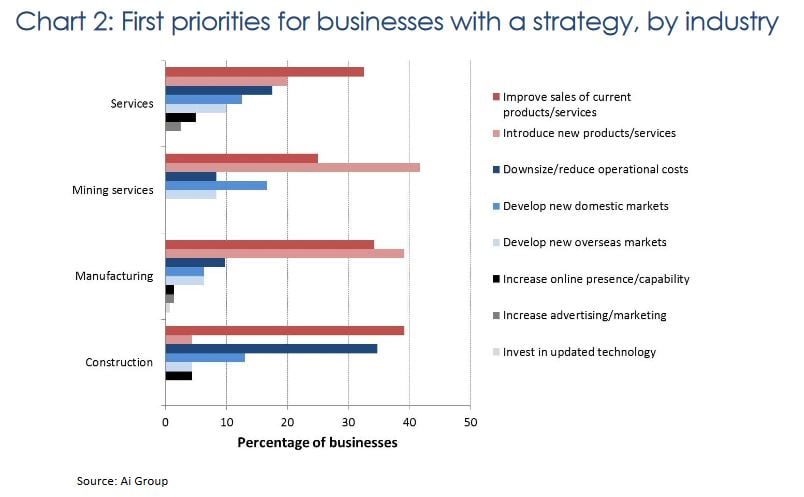

However, the report suggests, the opposite is true, with the key priority for manufacturers in 2016 being investment in new products and services.

This focus mimics the wider findings of the report with 32% of businesses nominating this as their top priority in 2016.

However manufacturing were found ‘to be the most focused on creating new products’ with 39% of manufacturers noting that it was their top priority:

Reducing operational costs

While manufacturers are less focused on reducing operational costs (with only 10% counting it as an intrinsic part of their growth strategy), the trend towards ‘lean manufacturing’ continues to gain momentum.

The Australian reported that one of the reasons for the slow adoption of lean manufacturing concepts might be the Australian ‘she’ll-be-right mentality’, but when quizzed on the issue, AIG chief executive Innes Willox told The Australian, that the need for change was clear.

"The need to strengthen productivity and develop leaders with process improvement capability is an urgent issue within Australian industry."

It is important here to note that cost isn’t the biggest priority for customers selecting Australian goods, particularly in international markets. The Australian Manufacturing Growth Centre discovered ‘when Australian firms succeed in global markets, it is usually by providing the best products rather than just the cheapest products.’

However, the report also suggests, that Australia can’t afford to ignore reducing costs entirely. They note that the "Australian manufacturing companies, no matter how big, or small, can improve their operations by the introduction of process improvement".

One of the most effective ways to do this, is to embrace technology and to innovate.

Technologies driving innovation

More than 40% of businesses who were able to innovate admitted they saw increased revenue and improved customer service as a result of these investments. While 99% of manufacturing CEOs did not rank ‘invest in updated technology’ as their biggest priority on 2016, it is still ranked highly in business priorities.

SPC invested in new technology and in addition to the benefits of real time connectivity between their production systems and other business systems, they are seeing the benefits of even greater quality and efficiency. SPC realised a return on investment which was estimated at $500,000 in the first year.

They aren’t alone, a major Australian supermarket company invested in new technology and optimised their supply chain, increasing shelf life of their products by an average of 1.5 days and eliminated their storage requirements, with the products now being shipped directly to stores, yielding savings of $50 per pallet.

The Benefits of building a business strategy

The report shows that for businesses to move forward, they must be more ambitious and make innovation a bigger part of their growth strategy.

Even though there’s lots of positives to come out of this year’s report, it also highlights that there is still more work to be done. The report offers businesses a challenge, to be more innovative, more agile and to wisely invest in technological solutions, otherwise they risk falling behind.

To ensure your business is embracing technology and committed to being a leader in innovation, you need to get your BI projects across the line. To find out how to do it and create lasting change for your business, download our ebook Managing BI projects in manufacturing: the ultimate guide to effective change.